| 序号 | 采购操作 |

|---|---|

| 1 | |

XBC系列柴油机消防泵

产品概述

XBC系列柴油机消防泵组为本公司严格按照国家标准GB 6245-2006《消防泵》及美国消防协会标准NEPA20《离心消防泵的安装》等标准研制开发的一种新型消防设备(以下简称设备),该系列设备按所配用的消防泵(单级单吸式、单吸双吸式)可分为XBC-HS、XBC-IS、XBC-S型三个子系列,设备压力、流量范围广,其应用几乎满足消防所需的各种场合。

设备所配柴油机均采用国产或进口优质产品,具有启动特性好、过载能力强、结构紧凑、维修方便、使用简单、自动化程度高等特点,是一种先进、性能可靠的消防设备。

Product introduction

XBC series diesel engine fire-fighting pump group is a new-style fire-fighting equipment ("quipment" thereafter) developed by this Co.in accordance with GB 6245-2006 《Fire pumps》and 《NEPA20 Installation of centrifugal fire-fighting pumps》etc. standards and, upon the fitted fire-fighting pumps (single-stage single-suction type and single-stage dual-suctiontype), canbedivided into XBC-HS, XBCIS and XBC-S three sub-series. The equipmenthas a wide range of pressure and temperature and can be used for almost every occasion necessary for fire-fighting.

The diesel engine fitted with the equipment is an excellent product domestic or imported, features good starting performance, strong overload capacity, compact structure, easy maintenance and use and high degree of automation. The equipment is really a fire-fighting one advanced and reliablein performance.

XBC系列柴油机消防/应急泵组

适用于各种场合的消防供水和应急供水。

XBC series diesel engine fire-fighting/emergency pump group

Applicable for water supply for fire service and emergency water supply.

移动式柴油机泵组

农用柴油机泵组常选用自吸泵组成,白吸泵是轻型移动式水泵。具有体积小,重量轻,性能优良,操作简便,使用可靠,维护容易,适用范围广等特点。它广泛地使用于农业排灌、工厂、矿山、建筑工地和日常生活的供水。

1、采用三角皮带传动时,动力机主轴和泵轴必须平行,皮带轮要对齐。其中心距不得小于两皮带轮直径的两倍。当水泵和动力机直联时,应配共同底盘,采用爪型弹性联轴器,用钢尺在联轴器部位检查,保证泵轴与动力机轴的同轴度。

2、白吸泵在起动前必须向泵体内灌满储水,以免影响自吸性能。严禁未加储水运转,防止烧坏密封件。离心泵起动前,先向泵内加水,待水充满进水管路及泵体后即可起动。

Agricultural diessel engine pump group

Agricultural diesel engine pump unit is generally composed of selfpriming pump. The self-priming pump is light moveable water pump. It has such advantages as small volume, light weight, excellent performance, convenient operation, reliabl e use, easy maintenance and wide applicable range. It can be widely used for agricul-tural irrigation and water supply in factory, mine,construction site and daily life.

1. When adopting triangle belt for transmission, the spindle of driving engine shall be parallel with pump shaft and the belt wheels shall be aligned. The central distance shall not be lower than twice of the diameter of the twobelt wheels. When the water pump is directly connected with the driving engine, they shall be equipped with same chassis.Adopt claw type flexible coupler and check the coupler part with steel rule to ensure the coaxiality of pump shaft and driving spindle.

2. Before the self-priming pump is started, water must be poured into the pump body to avoid influencing the self priming function. It is forbidden to operate without storing water to prevent the sealing parts being burnt. Before the centrifugal pump is started, first add water into the pump and start it until the water fills the inlet pipe and pump body.

农用柴油机泵组

农村灌溉,仓库、码头的消防和市政排水泵组常常采用移动式柴油机泵组,对于小型机组可采用人工手推式,对于大一些的机组则采用机动车牵引式。

Agricultural diessel engine pump group

Moveable diesel engine pump unit is commonly used in the fire and municipal water drainage pump unit for agricultural irrigation, warehouse and dock. For small type unit, manual pushing type can be adopted, and for larger unit,vehicle dragging type can be adopted.

结构特点及功能说明

设备由X6135、1 2V135、4102、4105、6102等系列柴油机为动力,柴油机(可配离合器)通过高弹性联轴器与消防泵联接组合成消防泵组,机组外还包括柴油箱、散热水箱、风扇、控制屏(自动机组用)等部件。

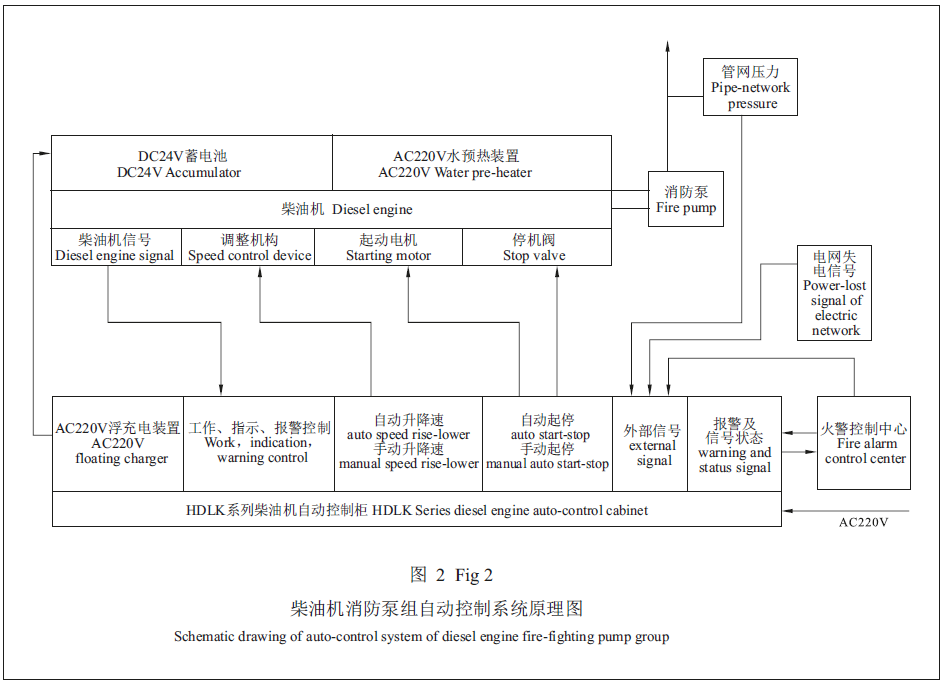

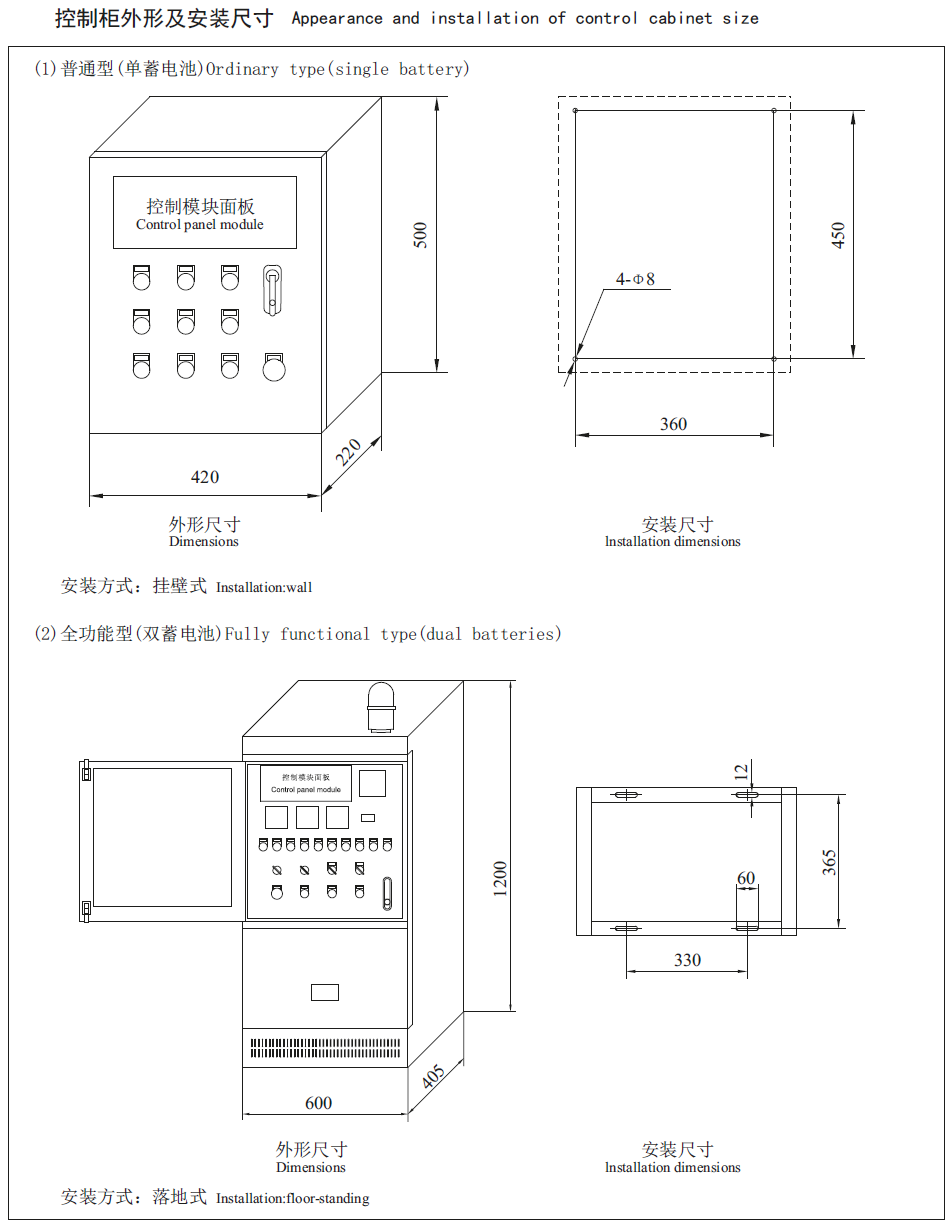

当为自动控制机组时,由分体式柴油机自动控制柜(可编程)实现系统的自动启动、投入、自动切换(电动泵组切换到柴油机泵组或该组柴泵切换到另一组柴油机泵组)、自动保护(柴油机超速、油压低、水温高、三次启动失败、油位低、蓄电池电压低等报警停机保护)等功能,同时还可与用户消防中心或火灾自动报警装置接口,实现远程监控。

为保证机组在低于5℃环境下正常工作,机组可附设AC220V冷却水预热加热装置。

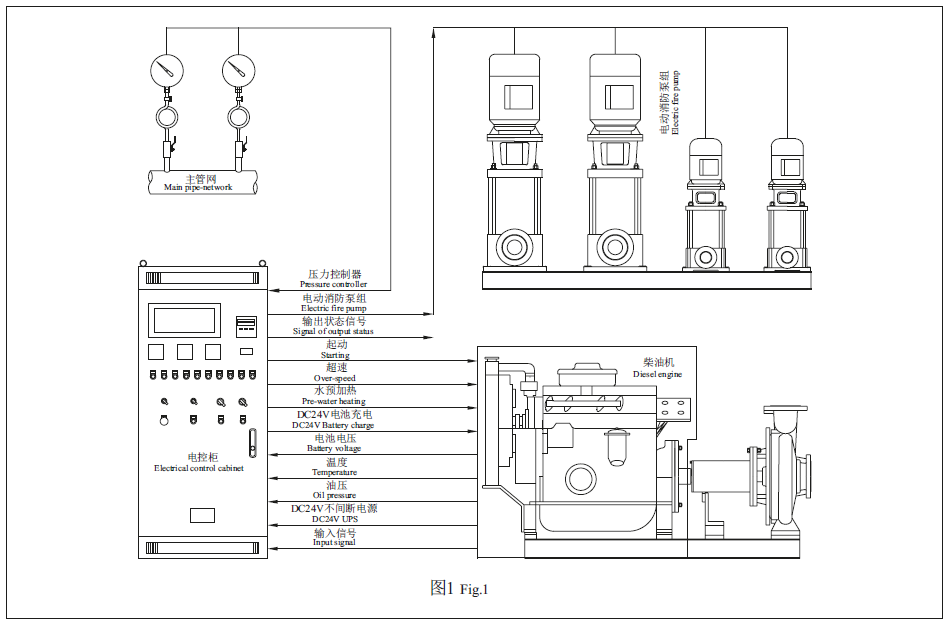

柴油机消防泵组可与电动泵组稳压泵等组成自动消防给水系统(见图l)。其工作过程见“柴油机控制系统”介绍。设备可与消防中心实现联控。

消防泵的进水方式有自灌和吸上两种,按消防规范要求,一般为自灌引水方式。如用户需吸上进水系统,需特别说明,以便公司提供自动真空引水装置,但泵组尺寸有所改变。

Structrral characteristic and functions

The equipment takes X6135, 12V135, 4102, 4105, 6102etc. Series diesel engines as the power and these dieselengines (can be fitted with clutches) are combined with fire-fighting pumps through high elastic clutches to form thefire-fighting pump group, including diesel tank, radiation water tank, blower, bontrol screen (for the auto group) etc.

Parts.

As the auto-control group, a separate diesel engine auto-control cabinet (programmable)carries out the system's automatic starting,putting into use, auto-switching (the motorpump group is swit ched to the diesel engine pump one orthediesel engine pump group to another group), auto-protection(warning and stopping protection for the diesel engine's over-speed, lower oil pressure, hogh water temperature, three times failures of starting, low voltage of accumulator etc.) etc. functions and also can be connected to fire-fighting centers of users or the autowarning device offire to get a remote moni-toring.

To ensure the group to normally working ambient temperature of below 5℃, it can be fitted with and AC220V cooling-water preheater.

The diesel engine fire-fighting pump group can be formed as an automatic fire-fighting water-supply system (see Fig.l) together with an electric pump one, pressure sta bilizing pump one etc. and the working process is introduced in"Diesel engine control system". The equipment can be jointly controlled with a fire-fighting center.

The mode of water inlet of a fire-fighting pump can be self-pouring and suction-up and, upon the requirement in the firefighting standard, the former is generally used. It needs to specially note in case of the need of the latter so as for this Co. To supply the automatic vacuum waterleading device, however, the dimensions of the pump group have to be changed somehow.

系统结构与原理 System structure and principle

自动消防供水系统能常由稳压泵、电动泵(主泵)、自动柴油机泵(备泵)组成,工作原理为:平常管网压力在P1(低压)-P2(高压)之间,低于Pl稳压泵起动,压力升至P2停泵,由于管网泄漏P2慢慢下降至Pl,稳压泵又起动,如此往复保持压力在P1-P2之间,当用水量大增,稳压泵无法维持Pl很快下降至P3,电动泵起动,压力上升至Pw并满足消防用水。如停电或电动泵有故障,压力由P3继续下降至P4则自动柴油机泵,压力上升至Pw并供水,电动泵或柴油泵停泵须人工判断后手动停泵,如估计管网泄漏较多,则需增加稳压罐或将稳压泵常开,以免起动频繁。

Electric fire-fighting water-supply system is generally formed with a pressure stabilizing pump, electric pump (main pump) and automatic diesel enging pump (spare one) and its principle of work comes like this: usually the pipe-network's pressure keeps in between P 1 (low one)- P2(high one).The stabilizing pump starts once the pressure be lows P 1 and stops when it rises to P2. It lowers slowly from P2 to P 1 due to the leakage of the network, the stabilizing pump starts again to keep it in between P l-P2.When the water quantity being use is greatly increased, the said pump can not keep the pressure at P 1 and it quickly lowers to P3, the electric pump

starts and the pressure rises to Pw (well) to meet with the demand for firefighting water. In case of power-off or a failure with the electric pump,the pressure goes on lowering from P3 to P4, the diesel engine pump automatically starts to have it rise to Pw for water supply.The electric pump or diesel engine one has to be stopped through artificial judgement and, if the leakage from the pipenetwork is estimated much, it is necessary to increase pressure stabilizing tanks or make the pressure stabilizing pump normally opened so as to avoid frequedt starting.

发动机冷却方式

一般情况下,本公司提供的机组柴油机冷却系统通常为闭式循环,发动机表面及散热水箱通过与其风扇产生的空气流进行热交换去实现发动机冷却。如需开式循环方式冷却(即用水泵输送冷却水与柴油机内循环水通过热效转换器实现发动机冷却)订货时要注明。

Cooling mode of generator

The cooling system of the oil engine supplied by this Co is generally in a closed cycle and functions cooling in such a way as both generator's surface and radiating water take heat exchange with the airflow produced by its blower. Please make a note at order if requiring an opened cycle of cooling(i.e.cooling of the generator is carried out by way of a heat exchanger between the cooling water transported through a water pump and the cycling water inside of the diesel engine).

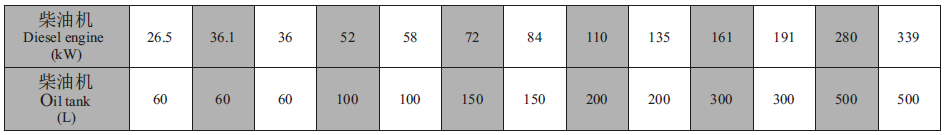

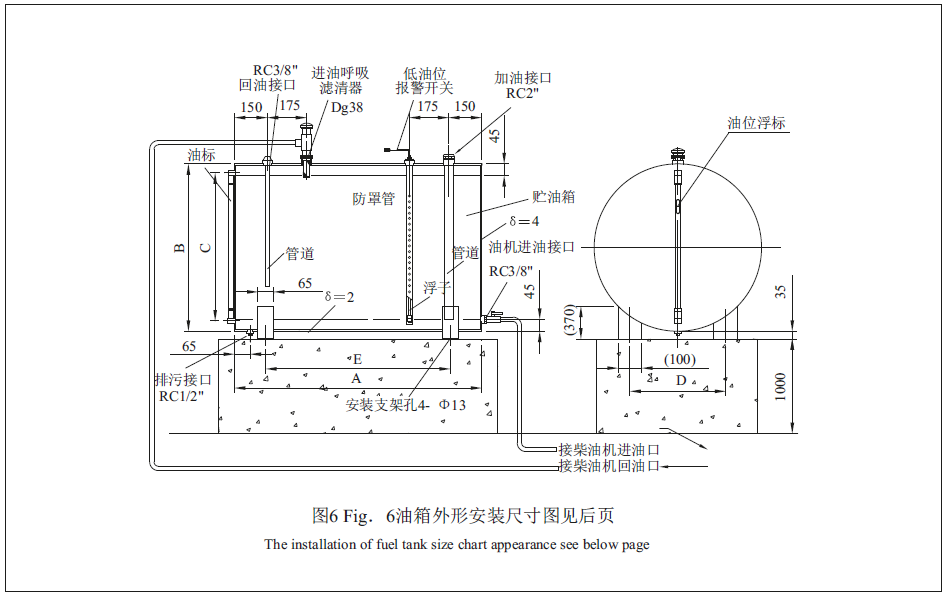

油箱的选用

功率在52kW以下的柴油机其油箱可直接安装在机组上,功率在52kW以上的柴油机油箱与机组分体。以下所列油箱容积可保证不同功率柴油机消防泵组6小时在额定工况下正常工作。

Selection of fuel tank

The oil tank used for the diesel engine of a power below 52kW can be directly mounted on the unit while the one for the diesel engine of a power over 52kW can be separated from the unit.The following listed oil tank's volumes can ensure the diesel engine fire-fighting pump groups of different powers to normally work under the rated working condition for 8 hours.

95系列柴油机小容量油箱直接安装在机组上,135系列柴油机油箱可按顾客要求定制成以下功能形式:

95 Series small capacity diesel fuel tanks installed in the unit directly,the 135 series diesel engine fuel tank can be custom-tailored into the form of the following functions:

设备安装注意事项

1、为保证机房内空气新鲜,避免大量热量散发在室内,降低噪声,应将柴油机排气管用石棉包裹接到室外并加装防雨装置或30°朝下安装,并加装消音器。排气管弯管尽可能少,弯管弯曲半径大于排气管外径的2.5倍,对排气管路的支撑应考虑降低振动且避免其重量加在柴油机上等因素。

2、消防泵进出口管网的安装,应注意其重量不允许加在消防泵上,以免泵受损和影响其运行性能。泵进口管路尽可能短而直。当进口为自灌时,管路朝泵方向上斜安装,确保管路内不会窝存空气。进水管口应设置滤网、挠性接头,出口管路上设置挠性接头、止回阀、闸阀。

3、不允许将控制柜安装在柴油机散热器的正前方,否则会影响柜内电器元件的正常工作。控制柜尽量布置在机组两侧或附近,以便操作方便。控制柜与柴油机之间的接线长度不得超过35m。

Installation Notes

1.To ensure a fresh air inside of the machine room,it is necessary to prevent lots of heat from radiating inside and lower the noise.wrap the exhaust pipe of the diesel engine with asbestos,extend it outdoor and mount a rain-proof device on it or mount it 30° downward and a silenser. The number of the elbow on it should be as less as possibe and the bent radius of the elbow should be over 2.5 times the outer diameter of the exhause pipe.take it into consideration for the support of the pipe to lower vib ration and prevent its weight from loading on the diesel engine.

2.When to mount both inlet and outlet pipes ofthe fire-fighting pump,do not let their weight loading on the pump SO as to prevent it against damage and its performance of running from being affected.The inlet pipe should be as short and straight as possible and,when it is as self-pourin9,it must be mounted upward tiltedly towards the pump to make sure no air exists inside of the pipe.A filter screen and flexible connector should be mounted on the inlet and flexible connector,check valve and gate vlave on the outlet.

3.It is not allowed to mount the control cabinet in the front ofthe diesel engine's radiator.otherwise the electric components inside of the cabinet would be affected and not work normally and it should be mounted on both sides of the unit or close to it,so as to get a convenient operation.The wiring between both control cabinet and diesel engine should not be over 35m.

设备的起停和运行

1、起动:首先确认消防泵的转向应正确,管网无水起动前,进口阀为常开,出口阀为常闭。无误后起动消防泵,当消防泵运转稳定逐渐打开出口阀门调到泵运行工况点。平时管网有水时出口阀为常开。

2、运行:消防泵转为正常运行时,应检查轴封和观察轴承的运行情况。机密密封的泄漏理应不超过3滴/分钟,填料密封的泄漏量应为点滴。轴承温度不应超过75℃,温升不应超过35℃,消防泵运行过程中如有异常声音应停止检查。

3、停泵前一般先关泵组出口阀门,再停柴油机。

Star,stop and run of the equipment

1. Start: first make sure of the correct rorating direction of the fire fighting pump and the inlet valve is as N.O and outlet valve N.C. Before the pipe network starts with no water.A tier n o error is found, start the

fire-fighting pump and,when the pump gets stable run, gradually open the outlet valve and adjust it to the work condition point for the pump to run.The outlet valve is N.O.when the network is filled with water at usual.

2. Run:when the pump gets a normal run, check the shaft seal and the bearing to see how it works. The leakage for the mechanical seal should not be over 3 draops/min and for the stuffing seal should be dot drop. The beating's temperature should not be over 75℃, and its temperature rise not over 35℃, Stop running for a checking case of an abnormal sound during thepump's run.

3. To stop, first close the outlet valve, then the diesel engine.

设备的维护保养

1、根据消防规范要求,机组必须至少l 5天运行一次,运行时间不少于1 5分钟,以确保消防泵随时处于良好状态。

2、消防泵每次起泵时应检查轴封是否正常,是否需要调整或更换。

3、应定期加轴承润滑脂。

4、如消防泵长期停用应排尽泵腔内水液,以防环境温度过低冻裂泵体等零部件。

5、根据柴油机保养规定应及时对柴油机进行日常维护和保养,检查冷却水量、机油量、电瓶电压、油压表、温度表、转速表及其它控制装置是否正常。

Equipment maintenance

1. According to the requirement in the fire-fighting standard, the unit must run once at least every 15-day with time not less than 15minutes so as make sure of it in a good status at any time.

2. Every time to start the fire-fighting opump, it should be done to check if the shaft seal is normal and if it needs to be adjusted or replaced.

3. Periodically lubricate the bearing with grease.

4. Completely drain the water inside of the pump out in case of a long time stop of the opump to prevent the pump casing etc.Parts from being frozen to result in split due to extra low ambient temperature.

5. According to the provision for the maintenance of the diesel engine, daily maintenance should be kept for it by checking if the cooling water quantity, engine oil quaqntity, the accumulator's voltage, oil pressure meter, thermometer, speed-ometer and other control devices are normal.

故障原因及排除方法Causes to failures and recovery

|

故障现象 |

可能产生的原因 Possible Causes |

排除方法 Recovery |

|

1、水泵不出水 |

a.进出口阀门未打开,进出管路阻塞,叶轮流道阻塞。 b.电机运转方向不对,电机缺相转速很慢。 c.吸入管漏气。 d.泵未灌满液体,泵腔内有空气。 e.进口供水不足,吸程过高,底阀漏水。 f.管路阻力过大,泵选型不当。 a.Inlet and outlet valves not opened,inlet and outlet pipeli.ne blocked.or impeller channel blocked. b.Improper turning direction of motor.low rotary speed due to phase absence of motor. c.Air leakage of suction pipe. d.Pump not filled up with liquid,and air existed inside pump chamber. e.Insufficient water supply of inlet,overhigh suction head,or leakage of bottom valve. f.Excessive pipeline resistance,or inappropriate selection of ump model. |

a.检查,去除阻塞物。 a.Check and clear away obstruction. |

|

2、水泵流量不足 |

a.先按1.原因检查。 a.Check it according to step l above. |

a.先按1.排除。 a.First recover according to measures in step 1 above. |

|

3、功率过大 |

a.超过额定流量使用。 a.Operation beyond rated flow. |

a.调节流量,关小出口阀门。 a.Adjust flow and lessen outlet valve. |

| 4、杂音振动 4.Noise andvibration |

a.管路支撑不稳。 a.Pipeline not steadily supported.

|

a.稳固管路。 a.Fix pipeline. |

| 5、柴油机故障 5.Diesel enginefault |

见《柴油机保养说明书》 See"Diesel Engine Maintenance Manual" |

见《柴油机保养说明书》 See"Diesel Engine Maintenance Manual" |

| 6、水泵漏水 6.Leakage ofpump |

a.机械密封磨损。 a.Mechanical seal damaged. |

a.更换。 a.Replace. |

选型依据

选择一套合理的给水设备的基本依据是设计的供水流量和供水压力(扬程),另外还需考虑到使用流量变化类型。

连续型:一天内很少有流量为零的时候,或本身管网的正常泄漏就保持有一定的流量,例如,大型宾馆,饭店,工矿企业的加压系统等。

间歇型:用水低谷时间较长且流量很小或为零,例:小型办公楼、写字楼、商住楼、各类住宅,及生产用水等。同时还应考虑在供水的某一段时间内流量的变化,以及不同季节流量的变化、不同地区用水的不同等因素。

消防泵以及喷淋泵一般与隔膜式气压罐、小流量稳压泵、电气控制设备组成一套恒压消防(喷淋)给水设备,因其长期处于系统保压状态,无流量的变化,气压式给水设备可以应付一般的管内的泄漏,并增加一台小流量的副泵,平时就无需启动主泵,节省能源。

变频给水设备的优点:可以恒压给水并且恒压值在一定范围内可调整,恒压精度一般小于0.02MPa,变频调速是一种高效节能的方法。与通常的气压给水设备相比平均节能20%,此外,变频启动的冲击电流小以及泵的运转冲击也小,在低速运转时噪声小。

气压式给水设备的优点:造价相对低廉,控制系统的技术简单,服务方便,维修简易。

The type selecting gist

The basic gist of selecting a set of reasonable water-giving equipment is the design water flux and pressure, plus the change type of the using flux.

Continuum modal:There is seldom the situation of zero flux in a day or the normal leakage of the pipe-net own keeping afirmed flux, for instance, the bigsize hotel, restaurant, the adding pressure system for industrial and mineral enterprises etc.

Intermission modal:The time of using little water is quite long, even zero, for example,a small-size office building, a writing building, a commercial-residing building, all kinds of dwelling houses and producing water etc.Meanwhile, the flux change in a some time or for different seasons and the different water-using volume in the different regions should be taken in to consideration. Fire-fighting pump and spraying pump usually matched with diaphragm air-pressure tank, little flux stablepressure pump and electric control equipment firm a set of constant-pressure firefighting (spraying) water-giving equipme nts. Under the pressure-keeping situation for a long time, no flux change, no need of starting the main pump because air-com pressing water-giving equipment plus a little flux vice pump can compen-sate the pressure loss for the normal leakage, so the energy can be saved.

The advantages of the frequency conversion equipment:Giving water at a constant pressure,and adjustable constant pressure in a some range, the tolerance of the constant pressure is usually less than 0.02MPa, The frequency conversion speed adjustment is a highly efficient energy-saving method, which can save 20% more than doing of the common air-co mpressing water-giving equipment, Moreover, the impacting current under starting of frequency conversion is small, also the running impact of the pump is small, so the noise is very small at a low speed.

The advantages of the air-compressing water-giving equipment: quite low making cost, easy-operation control system and convenient maintenance.

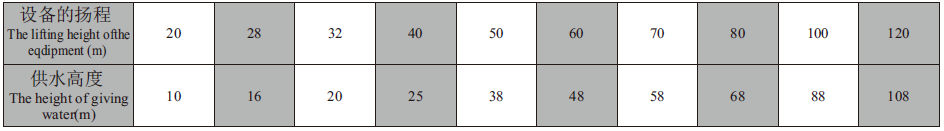

选型指南Selection guide

一、消防泵的选择The selection ofthe fire-fighting pump.

1、消防泵组供水高度的选择 The height of giving water for the fire-fighting group.

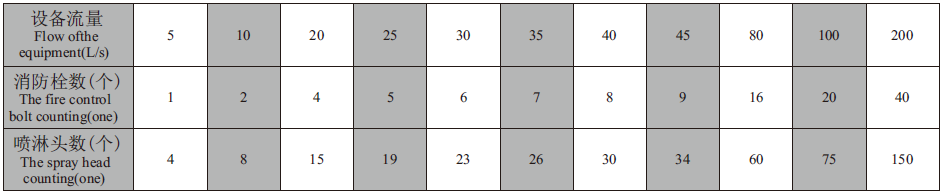

2、消防泵组流量的选择 Choice of group'S flow ofthe fire control pump

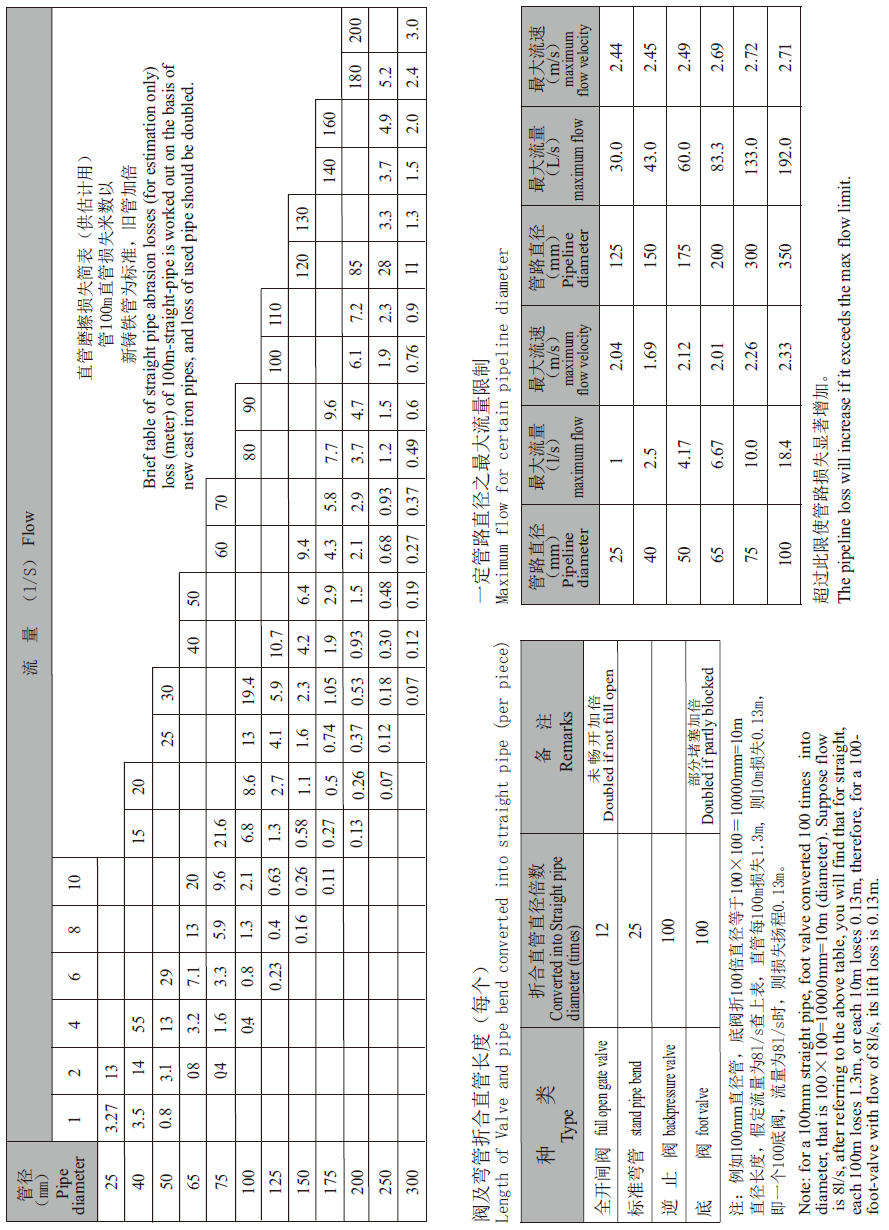

管路损耗参考表Reference Table of Pipeline Loss

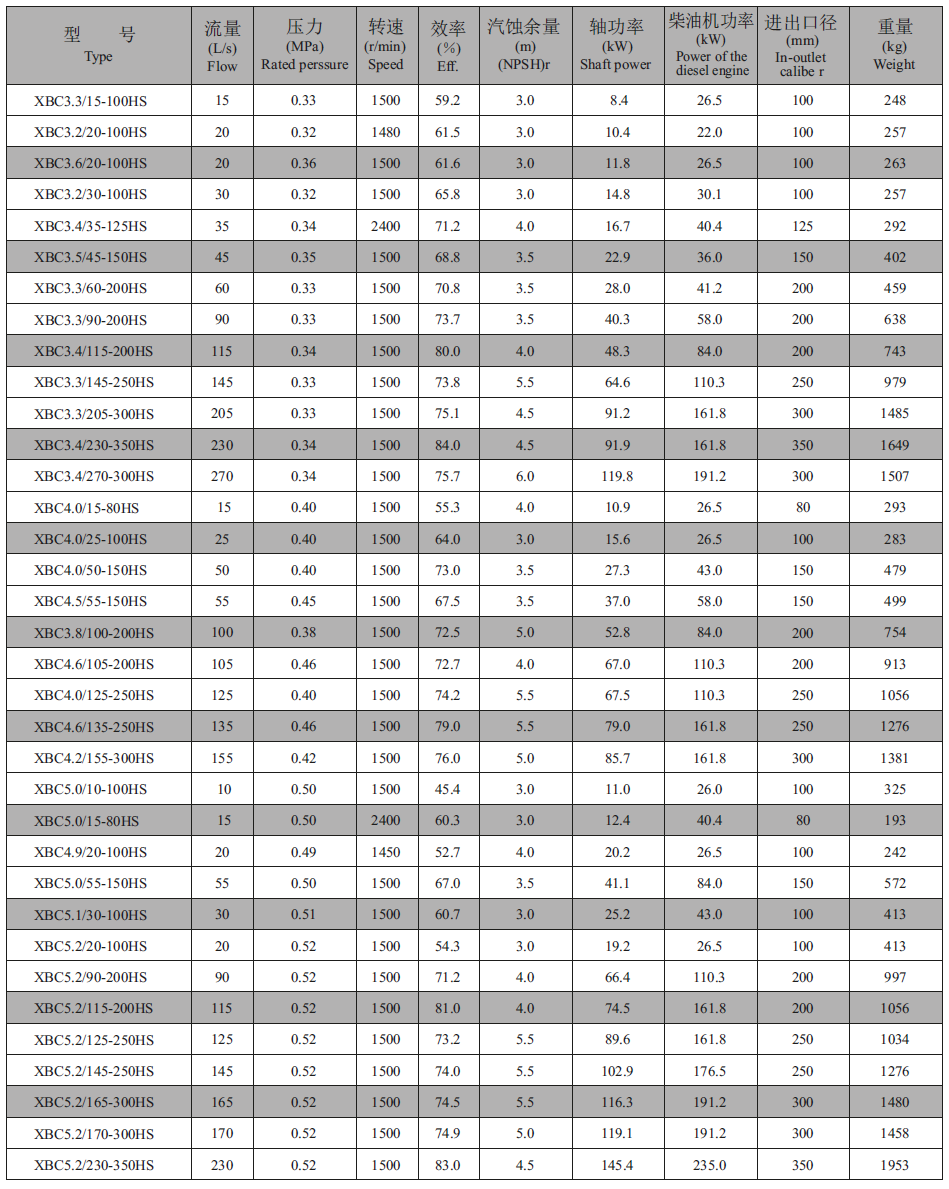

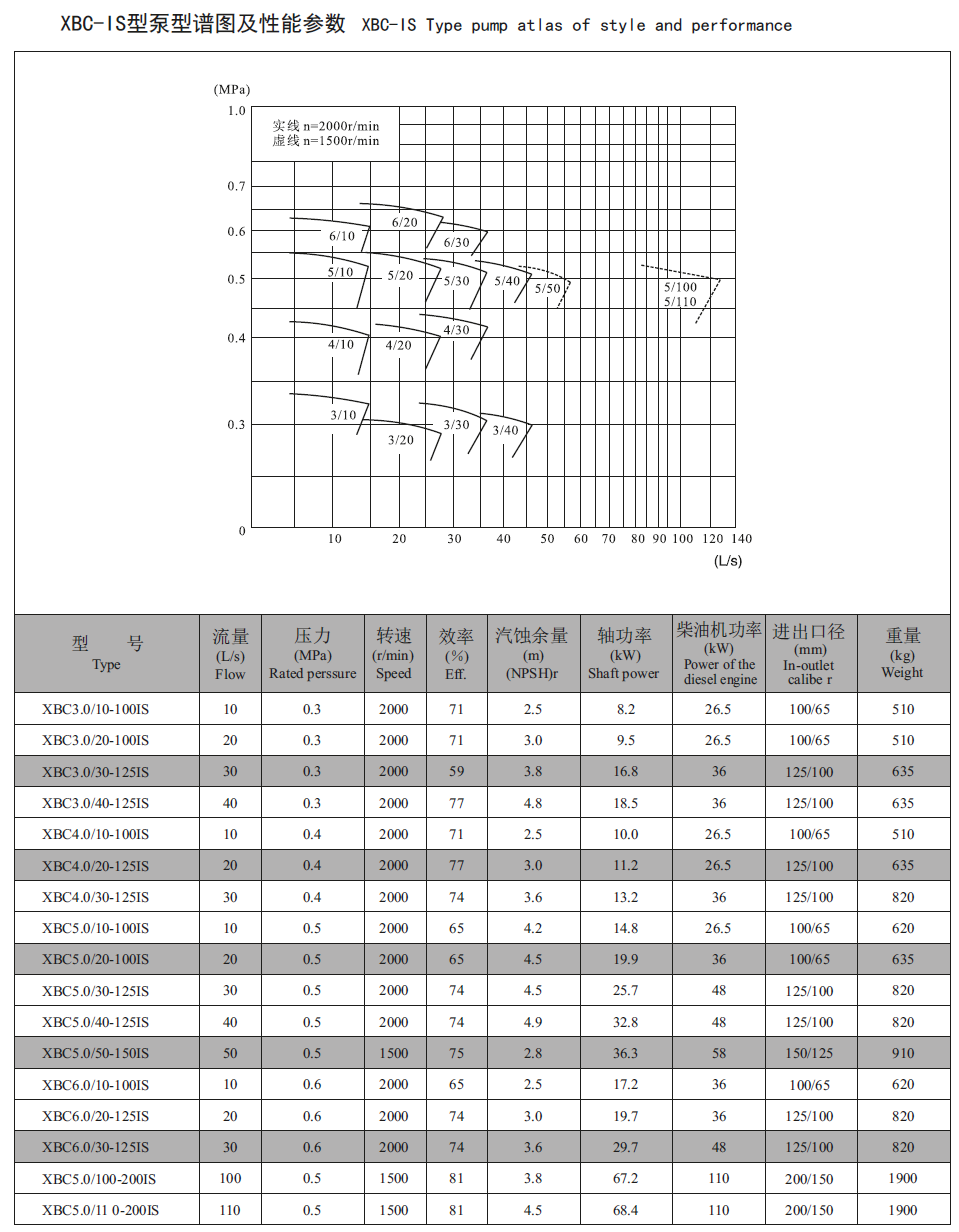

XBC-HS型柴油机消防泵组性能参数 XBC-HS Type diesel engine fire pump performance parameters